Always a pleasure to see others use proper mounting methods ie fuse holder, instead of using electric tape or cable ties n wrapping to existing wires.

My functional 'factory' install.

40 posts

• Page 2 of 3 • 1, 2, 3

Re: My functional 'factory' install.

Good to see further process in this install

Always a pleasure to see others use proper mounting methods ie fuse holder, instead of using electric tape or cable ties n wrapping to existing wires.

Always a pleasure to see others use proper mounting methods ie fuse holder, instead of using electric tape or cable ties n wrapping to existing wires.

08 H6 Liberty Wagon Stealth Install

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

- andy85

- Posts: 533

- Joined: Fri Jan 22, 2010 9:26 am

- Location: Sydney

- Car: MY08 H6 Wagon Tuned by KiDo Racing

- Real name: Andrew

Re: My functional 'factory' install.

hehehe, Funny story about that, a few weeks ago I fitted a sub and amp to my mates Falcon. It had already had an interior speaker and amp upgrade and when I went to find the earthing point for his existing amp so I could run the Sub Amp off the same ground point I discovered it was attached to one of the mounting bolts for his LPG Tank!!!! (OMFG!!!). Not only is that dangerous it is also ADR Illegal (for obvious reasons).

Found out this quality craftsmanship was done by none other than WOW Sight and Sound!!! <---FAIL

There are reasons I go the extra mile, I am begining to belive that car audio fitting as a profession needs to become a trade qualified job.

Found out this quality craftsmanship was done by none other than WOW Sight and Sound!!! <---FAIL

There are reasons I go the extra mile, I am begining to belive that car audio fitting as a profession needs to become a trade qualified job.

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

solongaudi wrote:hehehe, Funny story about that, a few weeks ago I fitted a sub and amp to my mates Falcon. It had already had an interior speaker and amp upgrade and when I went to find the earthing point for his existing amp so I could run the Sub Amp off the same ground point I discovered it was attached to one of the mounting bolts for his LPG Tank!!!! (OMFG!!!). Not only is that dangerous it is also ADR Illegal (for obvious reasons).

Found out this quality craftsmanship was done by none other than WOW Sight and Sound!!! <---FAIL

There are reasons I go the extra mile, I am begining to belive that car audio fitting as a profession needs to become a trade qualified job.

OMFG indeed!! Thats really asking for it.

I too really think it should become a trade qualified job. I cannot stress it anymore to my mates about car audio installations. I tell them all......INSTALLATION MATTERS!!! So what did this mate of mine did? He didnt take any of my advice and took it to a so called "PRO" installer. Half the price of FHRX n now going to end up costing more since i told him to get it redone properly!! These bastards didnt even solder the wiring to the amps... can clearly see its been twisted and pushed right in. No cable ties but a mess of electrical tape, they could've at least put some effort and line up then CUT the tape, instead they pulled it which gave it a really "kids" kind of install. Fuse was cable tied to some existing wiring in the engine bay... At the end of the day I just hope some people understands do it ONCE and do it RIGHT.

08 H6 Liberty Wagon Stealth Install

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

- andy85

- Posts: 533

- Joined: Fri Jan 22, 2010 9:26 am

- Location: Sydney

- Car: MY08 H6 Wagon Tuned by KiDo Racing

- Real name: Andrew

Re: My functional 'factory' install.

andy85 wrote:solongaudi wrote:hehehe, Funny story about that, a few weeks ago I fitted a sub and amp to my mates Falcon. It had already had an interior speaker and amp upgrade and when I went to find the earthing point for his existing amp so I could run the Sub Amp off the same ground point I discovered it was attached to one of the mounting bolts for his LPG Tank!!!! (OMFG!!!). Not only is that dangerous it is also ADR Illegal (for obvious reasons).

Found out this quality craftsmanship was done by none other than WOW Sight and Sound!!! <---FAIL

There are reasons I go the extra mile, I am begining to belive that car audio fitting as a profession needs to become a trade qualified job.

OMFG indeed!! Thats really asking for it.

I too really think it should become a trade qualified job. I cannot stress it anymore to my mates about car audio installations. I tell them all......INSTALLATION MATTERS!!! So what did this mate of mine did? He didnt take any of my advice and took it to a so called "PRO" installer. Half the price of FHRX n now going to end up costing more since i told him to get it redone properly!! These bastards didnt even solder the wiring to the amps... can clearly see its been twisted and pushed right in. No cable ties but a mess of electrical tape, they could've at least put some effort and line up then CUT the tape, instead they pulled it which gave it a really "kids" kind of install. Fuse was cable tied to some existing wiring in the engine bay... At the end of the day I just hope some people understands do it ONCE and do it RIGHT.

Sigh, I've been known to use sparky tape in a pinch, but I still solder and cable tie, and never along engine wires, and taping a fuse box to other parts that move is asking for a catastraphic failure. Especially in the event of an accident. I'm a fan of soldering, if I use lugs then I solder them too and then heatshrink the terminals... it's long, slow, tedious but it looks fantastic and I've never had a connection fail. So well worth the effort...

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

solongaudi wrote:andy85 wrote:solongaudi wrote:hehehe, Funny story about that, a few weeks ago I fitted a sub and amp to my mates Falcon. It had already had an interior speaker and amp upgrade and when I went to find the earthing point for his existing amp so I could run the Sub Amp off the same ground point I discovered it was attached to one of the mounting bolts for his LPG Tank!!!! (OMFG!!!). Not only is that dangerous it is also ADR Illegal (for obvious reasons).

Found out this quality craftsmanship was done by none other than WOW Sight and Sound!!! <---FAIL

There are reasons I go the extra mile, I am begining to belive that car audio fitting as a profession needs to become a trade qualified job.

OMFG indeed!! Thats really asking for it.

I too really think it should become a trade qualified job. I cannot stress it anymore to my mates about car audio installations. I tell them all......INSTALLATION MATTERS!!! So what did this mate of mine did? He didnt take any of my advice and took it to a so called "PRO" installer. Half the price of FHRX n now going to end up costing more since i told him to get it redone properly!! These bastards didnt even solder the wiring to the amps... can clearly see its been twisted and pushed right in. No cable ties but a mess of electrical tape, they could've at least put some effort and line up then CUT the tape, instead they pulled it which gave it a really "kids" kind of install. Fuse was cable tied to some existing wiring in the engine bay... At the end of the day I just hope some people understands do it ONCE and do it RIGHT.

I'm a fan of soldering, if I use lugs then I solder them too and then heatshrink the terminals... it's long, slow, tedious but it looks fantastic and I've never had a connection fail. So well worth the effort...

+1

08 H6 Liberty Wagon Stealth Install

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

Processor - BitOne

Front Stage - Crescendo 8.9B | Front Amp - Arc Audio KS300.4

Sub - IDMAX 10" | Sub Amp - Arc Audio KS1000.1

Wiring- Stinger | Battery - Stinger SPV44

Sound Deadening - Dynamat Xtreme | Entire Floor | Trunk | Trunk Lid | Doors

Installer - FHRX | Sound Deadening - Me, myself and I

- andy85

- Posts: 533

- Joined: Fri Jan 22, 2010 9:26 am

- Location: Sydney

- Car: MY08 H6 Wagon Tuned by KiDo Racing

- Real name: Andrew

Re: My functional 'factory' install.

Edited - I'm a dope

Last edited by dr20t on Sun Aug 05, 2012 10:56 am, edited 1 time in total.

-

dr20t - Posts: 4191

- Joined: Sun Oct 23, 2011 10:43 pm

- Location: South West Sydney NSW

- Car: 04 Liberty GT Auto

- Real name: Mick

- Profile URL: viewtopic.php?t=14137

Re: My functional 'factory' install.

Hrrmmm, Have you actually checked that twisting is better than soldering with your own multimeter??? Or is this an online claim from some dude you saw on a site you found on Google? I'd SERIOUSLY question that. I think you'd find the voltage drop is negligible neigh un-detectable. If solder was than much of an in-efficient conductor then why do they use it in computers which rely on a shift in voltage less than .01V to indicate 0 or 1? Admitedly that's silver solder not lead/nickel solder but seriously, if the voltage drop is that noticible I'd be checking for dry joints, not blaming an age old technique (bad tradesman blames his tools right?). I have these arguments with people all the time and when I try to prove I'm right mathematically and rip out my personal favorite Ohms Law (V=IR, P=IV) to prove my point (assumeing a voltage drop 0.01V@60A means 1.666Ohms, there fore the join is dissapateing 600mW! Not bloody likely!) and I usually get the response "Ohms law, thats that thing where if you put two 4ohm subs in parrellel it becomes 2 ohms right?" And they think they've then won the argument. So I'm not going to beat my head against a wall here. I'll just say, check things for yourself, never take anything (even what I say) as gospel, seeing is beliving. However, If you've read my previous posts, my electronics and sound experience goes way beyond the real of car audio....

I'm not crucifying people on crimping vs soldering etc. I'm crucifying people who do a shit job in general and try to palm themselves off as professionals. I was recently talking to a friend of mine who had his passenger side airbag deploy as he was driving his car away from WOW sight and sound! The shit "Proffesional Car Audio Fitter" didn't connect his capacitor properly and the hot, unfused, 12V 4G wire came out of its nice little socket. The resultant current shunt to ground then triped his airbag sensor. This deployed it at full force while he was driving. I have seen too many crimp joins fail so I solder, that is MY preferred technique as it is tried tested and proven. Remember a vehicle is not a static install, it is a moving install with unpredictable bumps and vibrations. You need redundancy in everything you do. If you want to see how stuff that gets abused is wired, look inside professional P.A. Gear or guitar amps, stuff that is BUILT to be abused and you will see many of the techniques I'm listing here employed.

Also to clarify, I don't solder directly to boards, I solder to crimps that then make a more solid connection benethe the grub screws, then I use some kind of cable relife as a redundancy. I don't get dry solder joints as I use appropriate heat for the task. I have a choice between a 25W electric soldering iron, 120W Gas Powered soldering iron and an LPG Gas Blow tourch (I use that for 4G and larger lol). There will be more clarification on this to follow as I get into the wiring phase, photo's will be included. Save your criticism till then, as stated, seeing is beliving.

If you have never had a crimp or a twist fail then cudos to you. I've had them fail on me so I now refuse to use them.

Also I ask you this... After reading some of these horror stories on shoddy installs, if that was you, would you go back to the same place who did such a turd job to begin with? Are your really sure none of your connections have ever failed? How do these places know their doing a shit job when people have lost so much faith after one install? It is usually guys like me who end up cleaning up these installs and thats why these so called professional installers swear by their techniques, cause their not the ones fixing the bloody things! But hey it makes me a buck on the side so I really should stop my bitching.

I'm not crucifying people on crimping vs soldering etc. I'm crucifying people who do a shit job in general and try to palm themselves off as professionals. I was recently talking to a friend of mine who had his passenger side airbag deploy as he was driving his car away from WOW sight and sound! The shit "Proffesional Car Audio Fitter" didn't connect his capacitor properly and the hot, unfused, 12V 4G wire came out of its nice little socket. The resultant current shunt to ground then triped his airbag sensor. This deployed it at full force while he was driving. I have seen too many crimp joins fail so I solder, that is MY preferred technique as it is tried tested and proven. Remember a vehicle is not a static install, it is a moving install with unpredictable bumps and vibrations. You need redundancy in everything you do. If you want to see how stuff that gets abused is wired, look inside professional P.A. Gear or guitar amps, stuff that is BUILT to be abused and you will see many of the techniques I'm listing here employed.

Also to clarify, I don't solder directly to boards, I solder to crimps that then make a more solid connection benethe the grub screws, then I use some kind of cable relife as a redundancy. I don't get dry solder joints as I use appropriate heat for the task. I have a choice between a 25W electric soldering iron, 120W Gas Powered soldering iron and an LPG Gas Blow tourch (I use that for 4G and larger lol). There will be more clarification on this to follow as I get into the wiring phase, photo's will be included. Save your criticism till then, as stated, seeing is beliving.

If you have never had a crimp or a twist fail then cudos to you. I've had them fail on me so I now refuse to use them.

Also I ask you this... After reading some of these horror stories on shoddy installs, if that was you, would you go back to the same place who did such a turd job to begin with? Are your really sure none of your connections have ever failed? How do these places know their doing a shit job when people have lost so much faith after one install? It is usually guys like me who end up cleaning up these installs and thats why these so called professional installers swear by their techniques, cause their not the ones fixing the bloody things! But hey it makes me a buck on the side so I really should stop my bitching.

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

Completely agree with everything said. an tree is mo doubt you have some great knowledge and skills which I would lbt come near to.

I have personally tested a twist joint using a mutlimeter, and the current drop wasn't any different in most instances, and in a couple of instances was better than a soldered joint.

I think youre also mistaking my words to mean that I'm against soldering (which is a ridiculous thing lol). I'm just saying in some situations certain wires are impractical to solder and a proper twist joint can be just as efficient.

I too always use lugs for amp wiring where possible, albeit certain power boards require a push in screw down power up which makes it difficult to use lugs.

I have personally tested a twist joint using a mutlimeter, and the current drop wasn't any different in most instances, and in a couple of instances was better than a soldered joint.

I think youre also mistaking my words to mean that I'm against soldering (which is a ridiculous thing lol). I'm just saying in some situations certain wires are impractical to solder and a proper twist joint can be just as efficient.

I too always use lugs for amp wiring where possible, albeit certain power boards require a push in screw down power up which makes it difficult to use lugs.

-

dr20t - Posts: 4191

- Joined: Sun Oct 23, 2011 10:43 pm

- Location: South West Sydney NSW

- Car: 04 Liberty GT Auto

- Real name: Mick

- Profile URL: viewtopic.php?t=14137

Re: My functional 'factory' install.

dr20t wrote:Completely agree with everything said. an tree is mo doubt you have some great knowledge and skills which I would lbt come near to.

I have personally tested a twist joint using a mutlimeter, and the current drop wasn't any different in most instances, and in a couple of instances was better than a soldered joint.

I think youre also mistaking my words to mean that I'm against soldering (which is a ridiculous thing lol). I'm just saying in some situations certain wires are impractical to solder and a proper twist joint can be just as efficient.

I too always use lugs for amp wiring where possible, albeit certain power boards require a push in screw down power up which makes it difficult to use lugs.

Fair enough, my only concern with twist joins is the reliability of them, perhaps I don't do them properly.... I too am trying to figure out the best way for those screw down joint to which you refer, one idea I've had is useing a 4 gauge ring lug and cuting off the actual ring, soldering hte sleve on then doing a drilling a half-depth hole for the grub screw to insert into, Will let you know how that pans out for me...

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

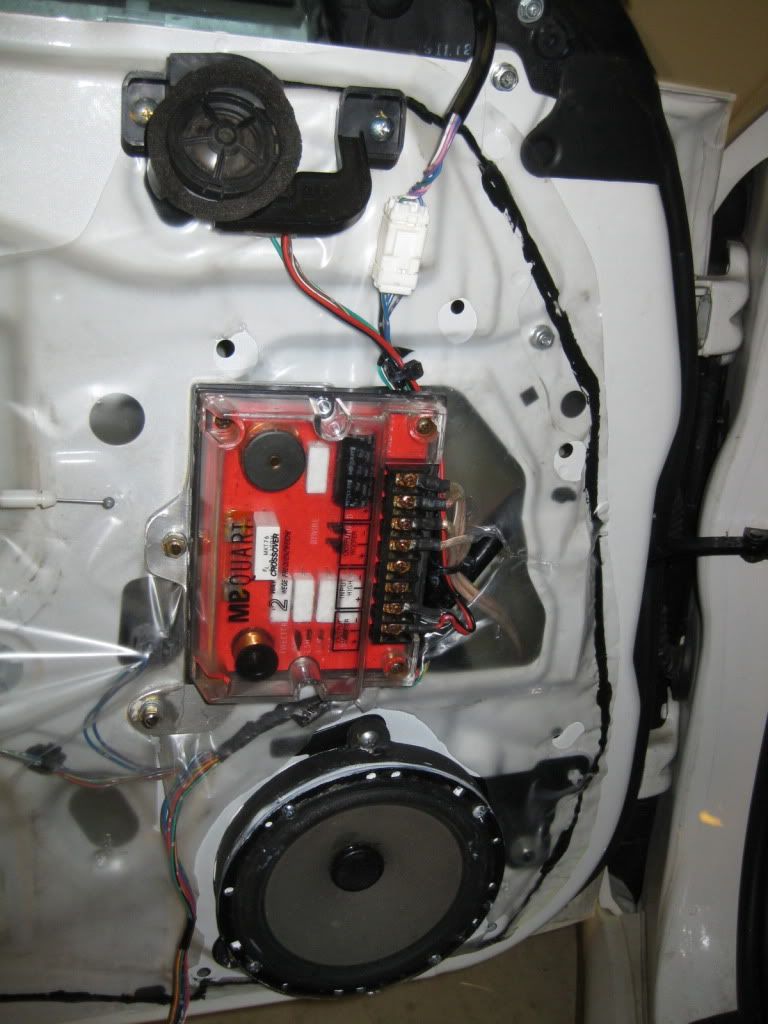

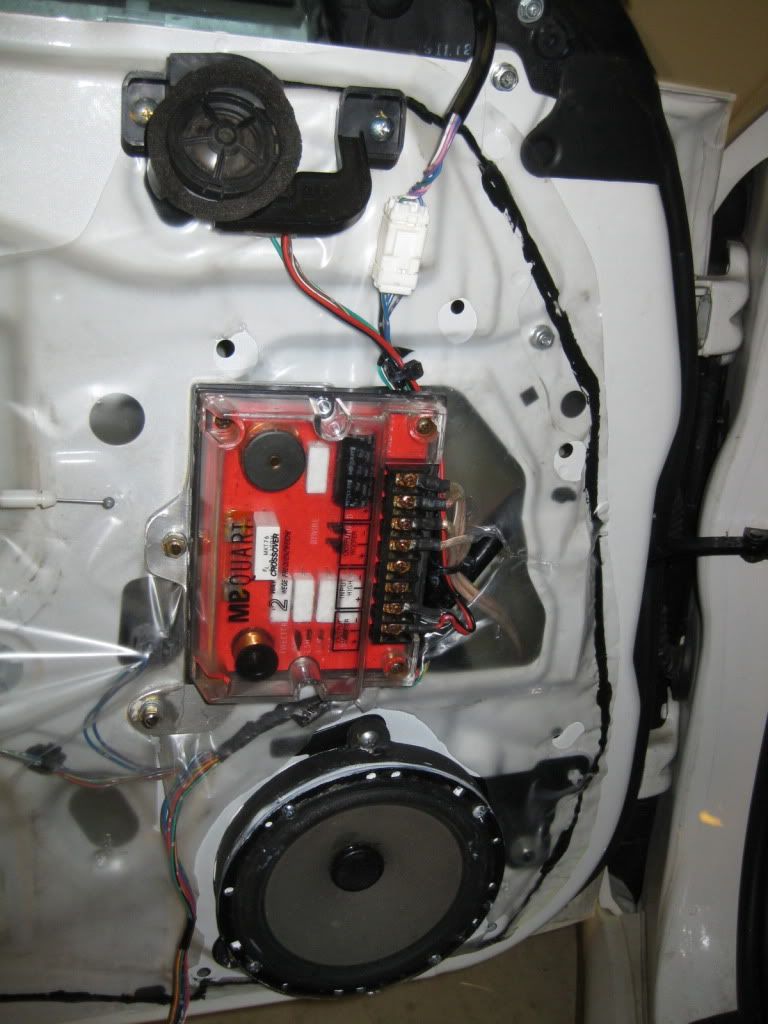

Thought I'd post up how to do the front speakers, I re-did them and took photo's of THAT install cause quite frankly the first round was a pathetic first attempt at this new 'factory replacement' tecnique I've been develouping. I learned a great deal though but I was too ashamed to post it  . So here is the new and improved 2nd attempt install of my front splits. Enjoy

. So here is the new and improved 2nd attempt install of my front splits. Enjoy  .

.

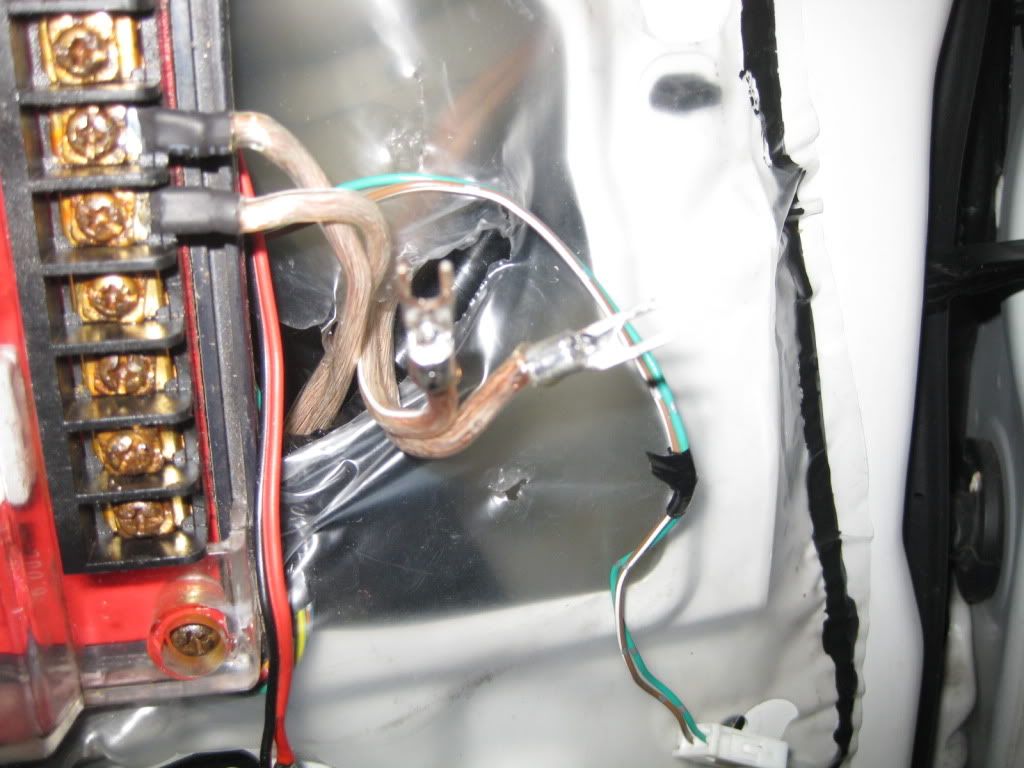

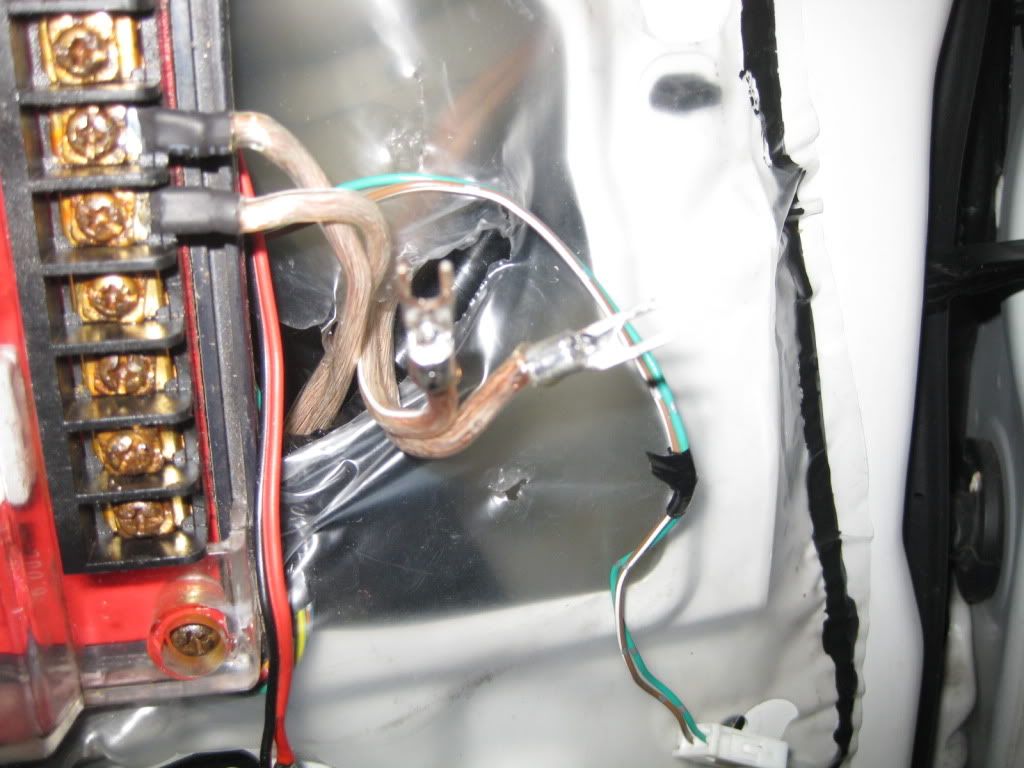

I found a perfect spot to mount the crossover that allowed the new speaker wires to run alongside the existing harness.

I used two factory holes that I assume are for the McIntosh Premium Audio "Midrange" speaker to mount an aluminium plate that the crossover could then bolt to. Personally I think 2-Way systems sound better.

Contrary to popular belife, crimping sucks for car audio (IMO please no more debate on this topic, this thread is not about debateing right or wrong, it's about my install). This is due to the amount of movement sustained in day to day driving. So I choose to solder and heatshrink for a far better result. You can even Colour code your heatshrink if your that way inclined, but I'm cheap so black it is.

A closer veiw of the new wiring, note I ran a new wire through from the passenger compartment into the door, I didn't just simply 'hack' into the original harness like so many 'Professional' installers do. What is the point of upgradeing the wire to handle more current if your just going to put it back into the 18G wire the factory gives you? Not to mention signal loss from having extra joints and connections.

The new tweeter is mounted to the factory mount via the same means, a single bolt through the magnet.

The new mdf adapters made up, painted and fited. It is sealed to the car with silicone to ensure no air escapes around the side and causes frequency cancellation.

A "small" amound of silicone is applied tot he back of the basket because this particular speaker does not have a foam gasket built it ?!? If you use silicone here be extreamly cautious and use it sparingly. Too much and it will enter into the driver and wreack your speaker. I recomend waiting till it cures (24hours at least) before actually turning it on to help prevent this from happening.

The Finished product with the door skin removed. The factory connections are zip tied away for safe keeping, NOT removed.

Viola, Wouldn't even know I've upgraded the front speakers, until you heard the difference that is . And all 100% reversible upon sale of the car.

. And all 100% reversible upon sale of the car.

I am also now posting this on facebook (search for "Kenn Melksham" under Car Audio Install photo album. There are descriptions under each photo, high resolution and the order is a little easier to follow for those who are interested. If you like what I'm doing and live in North QLD, give us a yell. I've been funding my system by installing systems for others.

Here's the link...

https://www.facebook.com/media/set/?set=a.2819734606738.140250.1060093838&type=3&l=ff830bc954

Keep an eye out, the Sub Woofer box mould casting is next, followed by fibreglassing and carpeting. Then we shall start wiring

I found a perfect spot to mount the crossover that allowed the new speaker wires to run alongside the existing harness.

I used two factory holes that I assume are for the McIntosh Premium Audio "Midrange" speaker to mount an aluminium plate that the crossover could then bolt to. Personally I think 2-Way systems sound better.

Contrary to popular belife, crimping sucks for car audio (IMO please no more debate on this topic, this thread is not about debateing right or wrong, it's about my install). This is due to the amount of movement sustained in day to day driving. So I choose to solder and heatshrink for a far better result. You can even Colour code your heatshrink if your that way inclined, but I'm cheap so black it is.

A closer veiw of the new wiring, note I ran a new wire through from the passenger compartment into the door, I didn't just simply 'hack' into the original harness like so many 'Professional' installers do. What is the point of upgradeing the wire to handle more current if your just going to put it back into the 18G wire the factory gives you? Not to mention signal loss from having extra joints and connections.

The new tweeter is mounted to the factory mount via the same means, a single bolt through the magnet.

The new mdf adapters made up, painted and fited. It is sealed to the car with silicone to ensure no air escapes around the side and causes frequency cancellation.

A "small" amound of silicone is applied tot he back of the basket because this particular speaker does not have a foam gasket built it ?!? If you use silicone here be extreamly cautious and use it sparingly. Too much and it will enter into the driver and wreack your speaker. I recomend waiting till it cures (24hours at least) before actually turning it on to help prevent this from happening.

The Finished product with the door skin removed. The factory connections are zip tied away for safe keeping, NOT removed.

Viola, Wouldn't even know I've upgraded the front speakers, until you heard the difference that is

I am also now posting this on facebook (search for "Kenn Melksham" under Car Audio Install photo album. There are descriptions under each photo, high resolution and the order is a little easier to follow for those who are interested. If you like what I'm doing and live in North QLD, give us a yell. I've been funding my system by installing systems for others.

Here's the link...

https://www.facebook.com/media/set/?set=a.2819734606738.140250.1060093838&type=3&l=ff830bc954

Keep an eye out, the Sub Woofer box mould casting is next, followed by fibreglassing and carpeting. Then we shall start wiring

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

Hey guys, wiring complete, this is very photo intensive so I've posted it on Facebook with blurbs on each photo, This includes a reverse camera input, Video and Audio In, Video Out, Sub Out and amlifier control. This is my best work yet. Took a whole week to do... Enjoy, let me know if the photos aren't visible, I did allow public access to this album.

https://www.facebook.com/media/set/?set=a.2819734606738.140250.1060093838&type=1

https://www.facebook.com/media/set/?set=a.2819734606738.140250.1060093838&type=1

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

Great work! I'm curious to see how you go about mounting the reverse camera. I'm hoping you have something in mind so it doesn't stick out

-

mynameisdaniel - Posts: 1224

- Joined: Mon Jun 13, 2011 1:47 pm

- Location: Adelaide, Australia

- Car: 07 Subaru Liberty GT tbSTi Sedan

- Real name: May or may not be Daniel

- Profile URL: viewtopic.php?f=10&t=15835

Re: My functional 'factory' install.

Needs moar Dynamat!!!

I'm not a massive fan of installing the X-Overs in the doors. THere is too much potential for them to be exposed to moisture etc. I always try and find somewhere under the dash to place them and wrap them with cable ties and faom padding for protection and minimise rattles. If you're planning on leaving the x-overs in the door I'd suggest something like wrapping them in foam padding, Dynamat (or equivalent) under the x-over and a layer over the x-over where sensible.

Other wise the install looks great. Keep up the good work, it's giving me some good information that will help with a major install I'm quoting on. I am quoting on an install on a GT-B and the front stage is looking like Dynaudio Esotar2 will be the hardware of choice... Me so excitement. If I get the go ahead it will be my last major install and will be something special. The owner wants a functional factory-ish install. No fancy pants fibreglass etc.

I'm not a massive fan of installing the X-Overs in the doors. THere is too much potential for them to be exposed to moisture etc. I always try and find somewhere under the dash to place them and wrap them with cable ties and faom padding for protection and minimise rattles. If you're planning on leaving the x-overs in the door I'd suggest something like wrapping them in foam padding, Dynamat (or equivalent) under the x-over and a layer over the x-over where sensible.

Other wise the install looks great. Keep up the good work, it's giving me some good information that will help with a major install I'm quoting on. I am quoting on an install on a GT-B and the front stage is looking like Dynaudio Esotar2 will be the hardware of choice... Me so excitement. If I get the go ahead it will be my last major install and will be something special. The owner wants a functional factory-ish install. No fancy pants fibreglass etc.

Car(s): Steel Silver MY10 GT Wagon + 1985 Subaru Sherpa

Mods: (GT) HKS Panel Filter. The HKS I put in the MY10 is the same filter I took out of my MY05 GT. So yes, they do fit. Custom leather heel pad to minimise carpet wear in the drivers footwell. Slotted front rotors. (Sherpa) 14'' 6 Spoke mags, Chrome Gear Shift (sick!), Alloy Pedals (sicker!), new positive and negative battery terminals, Alpine cda-9827 H/U, JBL GT 6x9's boxed and mounted (sickest!), Kicker DS650.2 component speakers mounted in the footwells in flibreglass pods, Alpine MRP-F200 4 channel amp (4x40wRMS), Rebadged with hektik chrome eBay badges, STi stickers for more powaaaa, "leather" handbrake boot, recarpetted with grey/black car carpet from Bunnings, sick Clarke Rubber boot mat, polished and waxed.

Mods: (GT) HKS Panel Filter. The HKS I put in the MY10 is the same filter I took out of my MY05 GT. So yes, they do fit. Custom leather heel pad to minimise carpet wear in the drivers footwell. Slotted front rotors. (Sherpa) 14'' 6 Spoke mags, Chrome Gear Shift (sick!), Alloy Pedals (sicker!), new positive and negative battery terminals, Alpine cda-9827 H/U, JBL GT 6x9's boxed and mounted (sickest!), Kicker DS650.2 component speakers mounted in the footwells in flibreglass pods, Alpine MRP-F200 4 channel amp (4x40wRMS), Rebadged with hektik chrome eBay badges, STi stickers for more powaaaa, "leather" handbrake boot, recarpetted with grey/black car carpet from Bunnings, sick Clarke Rubber boot mat, polished and waxed.

-

garbo41610 - -stickered-

- Posts: 1786

- Joined: Thu Jun 11, 2009 11:28 am

- Location: Emu Heights and Randwick depending on time of day

- Car: MY10 GT Wagon Steel Silver

- Real name: Phil

Re: My functional 'factory' install.

I totally agree with the dynamat... thats still to come, I'm doing little bits at a time, this time around was all about the wiring... I agree with your sentaments on the crossovers, thats why I mounted them high... but food for thought on the extra insulation, I'll see what I can come up with.

- solongaudi

- Posts: 83

- Joined: Thu Jan 13, 2011 5:15 pm

- Location: Townsville QLD

- Car: MY08 2.5i Manual Liberty

- Real name: Kenn Melksham

Re: My functional 'factory' install.

I get a "This content is currently unavailable" message when I click that link (logged out).

-

rooby - Posts: 2186

- Joined: Tue May 31, 2011 12:09 am

- Location: Canberra

- Car: MY07 Liberty GT Spec.B

- Real name: Reuben

40 posts

• Page 2 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 2 guests