I'm fairly new to the forum, my specialty is car audio. Here is my latest project on my 2008 2.5i.

The guidelines when I started this project were simple, It had to sound good (to appease me), not cost a fortune (to apease the bank balance) and still maintain the car's functionality (to apease the wife).

This meant trying to keep things as 'stock standard' as possible.

Here's what I am up to so far...

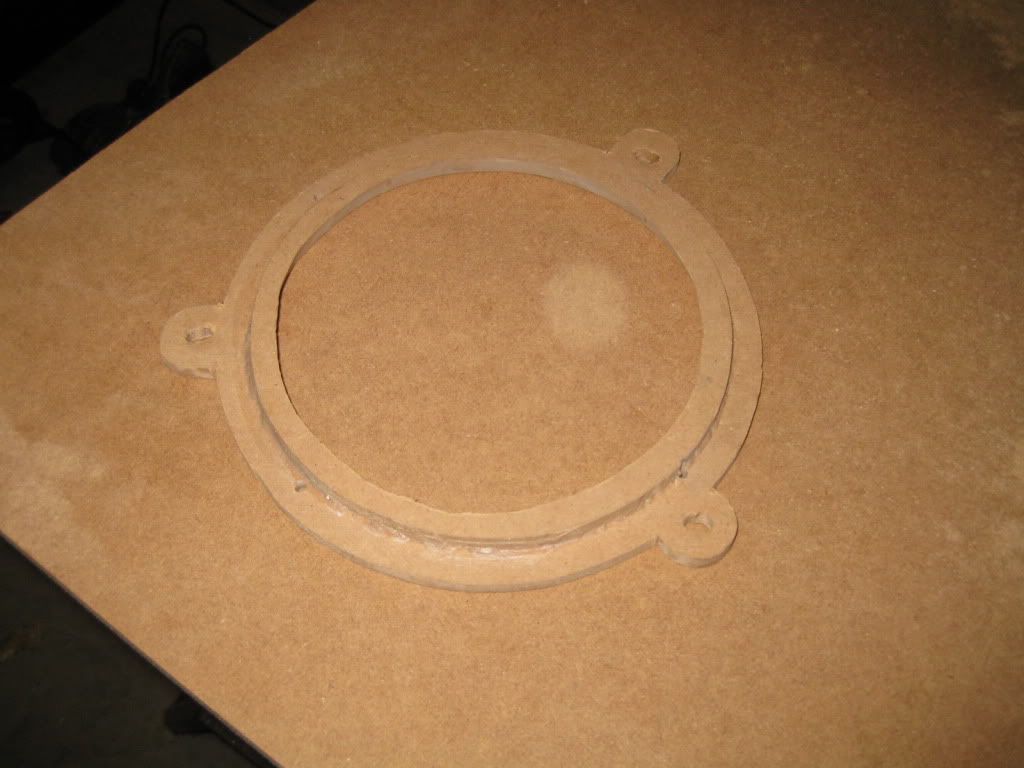

There is no point in showing pictures of the interior as it is the factory Kenwood AVN, and my MB Quart 6.5" Splits are sitting in the factory holes behind the factory grills with spacer plates so I didn't have to Drill a single thing, and the crossovers are under the dashboard to keep them away from water... The rear speakers are Rockford Fosgate Power 6.5" Coaxial (deep, not shallow) once again in the factory 5.25" hole with a home made mdf spacer behind the factory grills. So I have $1500 worth of speakers sitting in factory positions completely un-observable to the outside world. I can also revert to stock if I ever want to sell the car

I am installing the Steering wheel remote and the extended AV breakout harness to allow video In, Sub out and extension monitor out. The extenstion monitor out Outputs DVD or Aux Video in an NTSC composite signal so that you can have the map up on your main screen while the kiddies watch the Ninja Turtles on the DVD. Headrest Monitors will be the last stage of this install. Gold! I have also purchased an adapter to install a reversing camera, I have tested it, but the trick is I need to get a camera that outputs an NTSC signal, it is not compatable with PAL. I would also like to see if the Ipod controller from the US works with this head unit, It say's on the Subaru US website that it is compatable with the Kenwood AVN for the 2008-2009 Legacy and it's only $130, which I can sell on eBay if it doesn't work. Keep tuned, I'll invest the cash to see if it works and post the results at a later date. Of course I have done the Handbrake Ground mod so I can use the darn thing on the move.

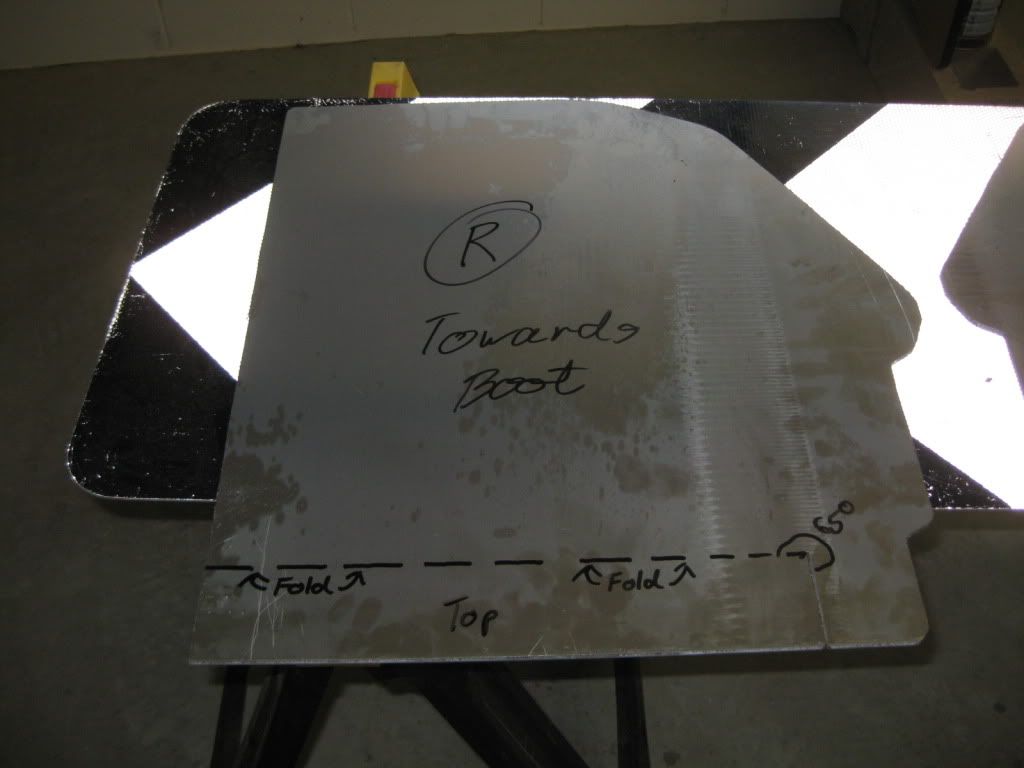

The Amp's havn't been mounted yet, they're going along the back wall of the boot after I've finished makeing these.... (to replace the 5mm Plastic Corflute).

They will be carpeted on the boot side with similar carpet to the rest of the boot and on the back seat side they will have the sound proofing glued back onto them. The biggest difference is I will weld the aluminium RHS (rectangular hollow section) uprights that are bolted to the chassis to give it some rigidity and add extra bolts along the top and side. I'll measure up the amps and fit them to the sheet prior to fitting to ensure they sit exactly how I want them, and then use multiple holes with rubber grommets so there is minimul wire exposed.

Note: Under the seats is NEVER a good option for amplifiers, or any electronics for that matter, as where does spilt coke go? Also makes the chips your kids inevitabley spill that much harder to vacuum up, easier for passengers to accidently kick wires out etc...

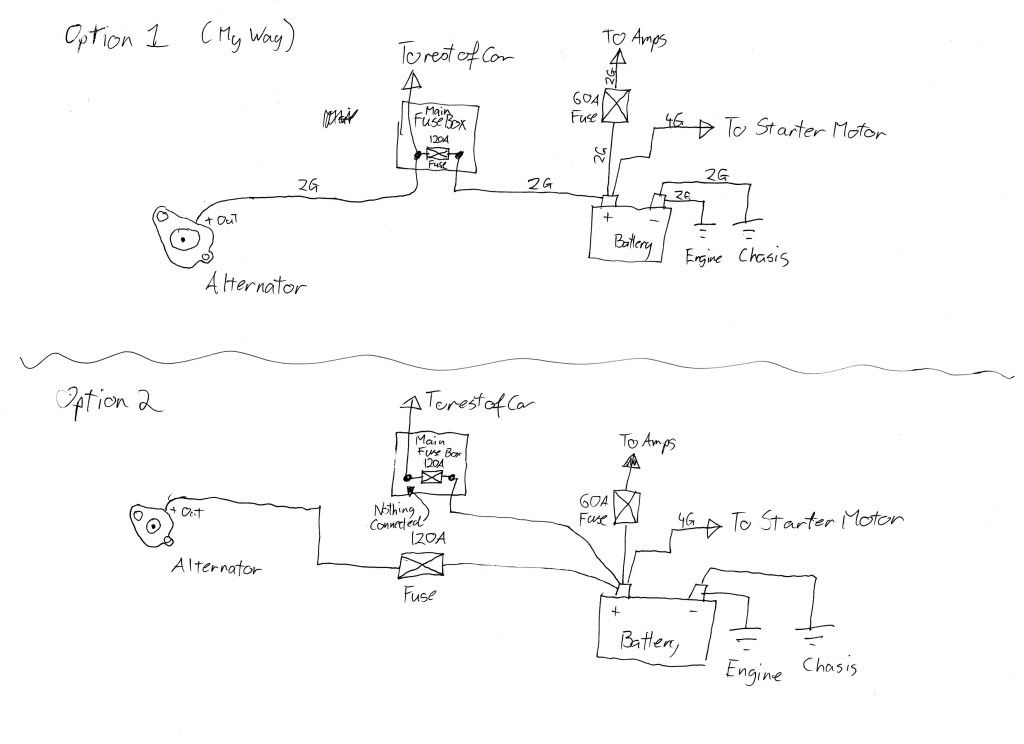

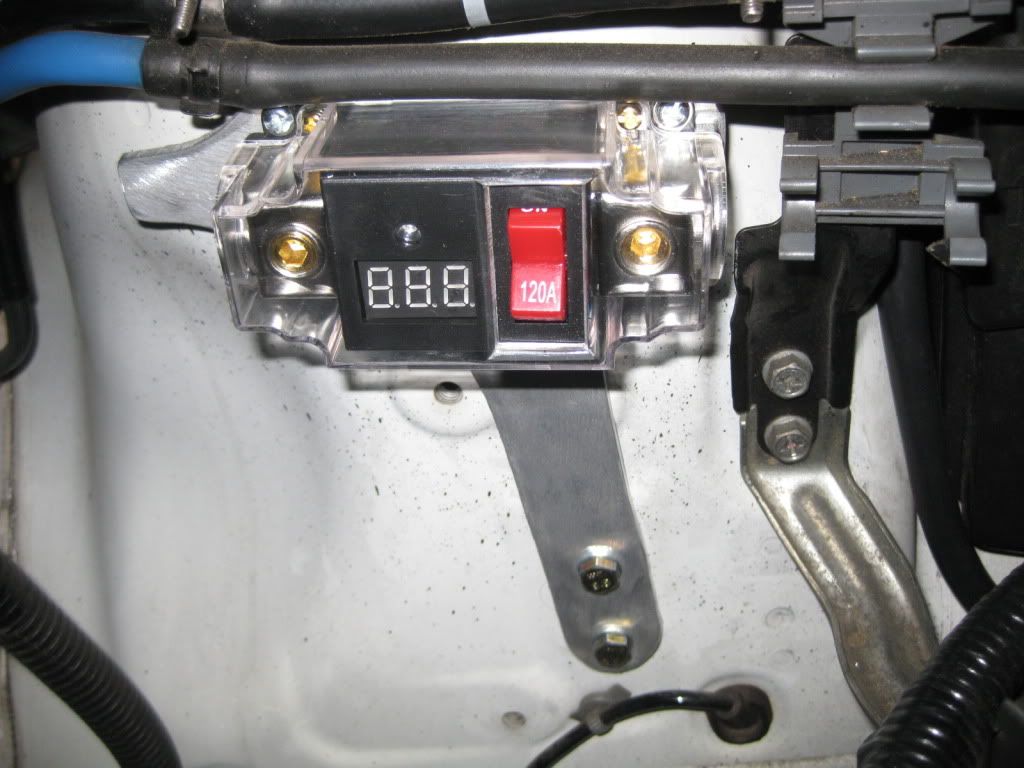

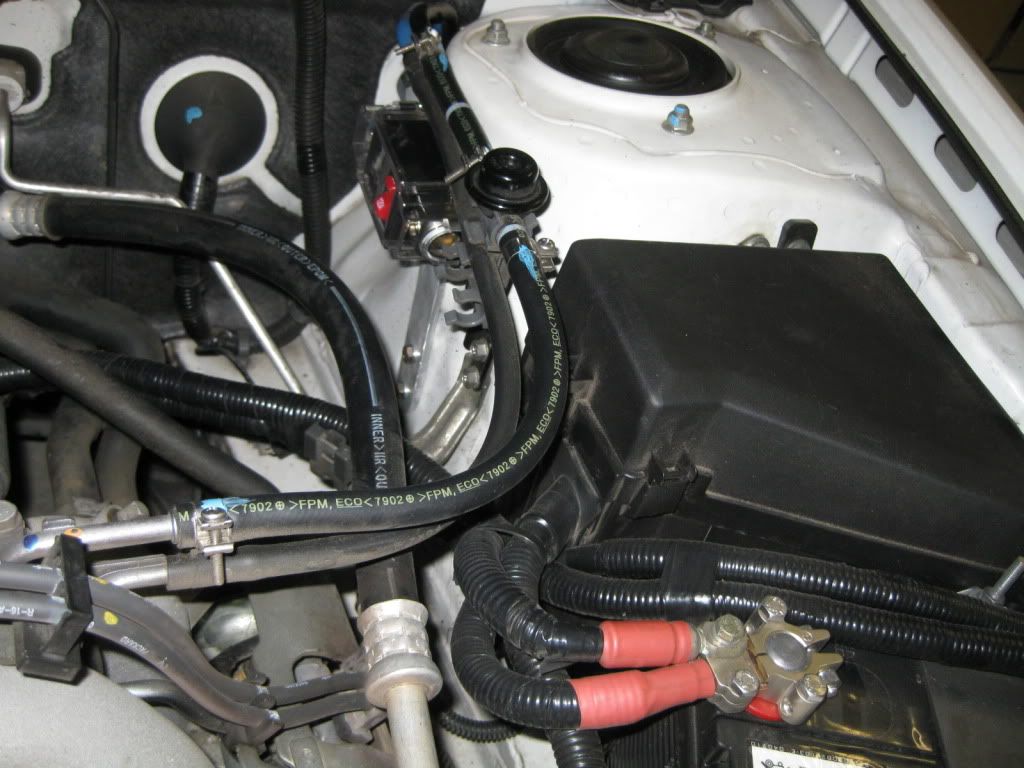

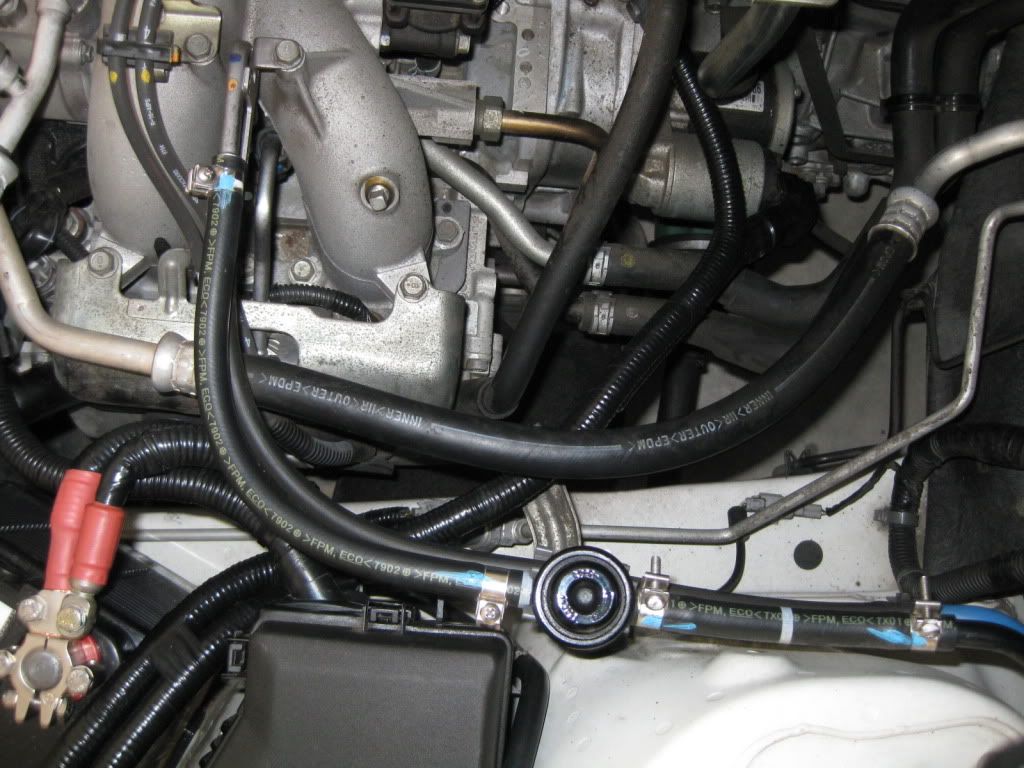

I've also upgraded the "BIG 3," Alternater(+) to Battery(+), Engine to Battery(-), Chasis to Battery(-). 2G cable all round AND managed to make it look factory, as well as horseshoe a 650CCA battery in

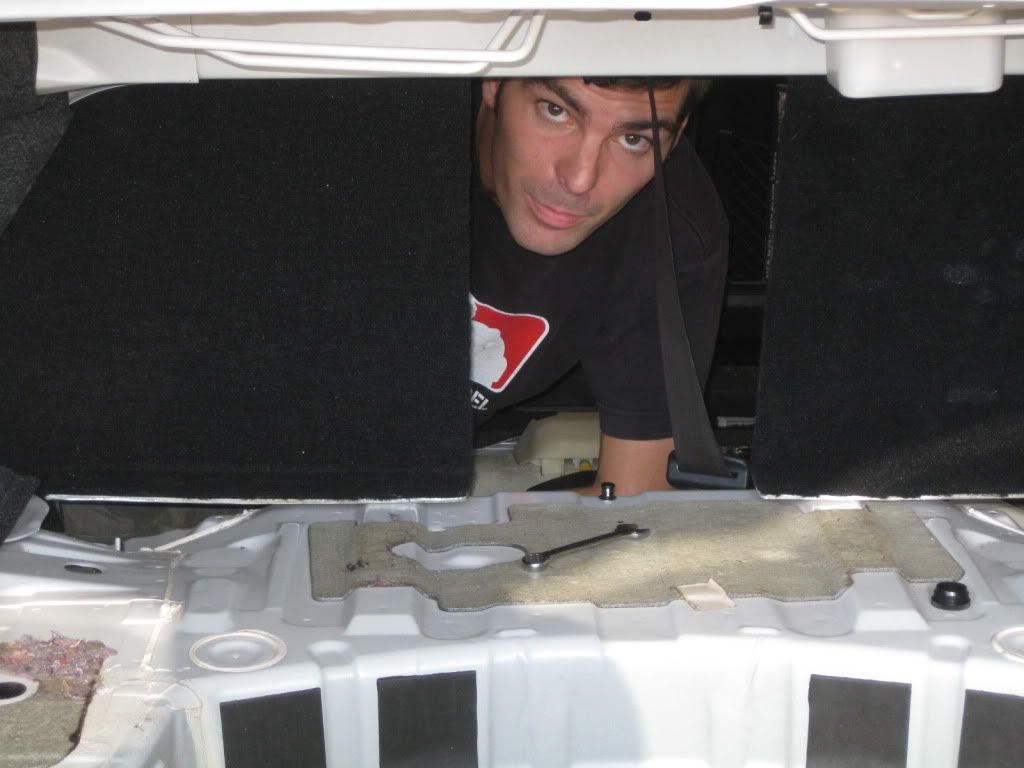

The boot is my "pièce de résistance." I am settling for 10" subwoffers as I prefer the tighter response even at the loss of a few dB below 40hz, so to make up for that I'm putting in two and giving them 600WRMS (not peak) to share at 2ohm. The boxes pictured below are yet to be fibreglassed but when they are finished they will be carpeted in the same colour material as the rest of the boot, and I can still get to the spare tyre. To overcome the lask of access to the rear lights I've upgraded to LED bulbs. Each box will be 21L when finished which is almost perfect for a sealed 10" box. The Grey carpet on the back wall is what is being replaced by that sheet of aluminium. Yes I kinda stole the idea for the sub box off LegacyGT.com but I've made a few changes like the MDF floorplate for stability of the baffle and the bolts into the chassis so that in the event of an accident my subs don't become 20kg missiles. I'm really big on not cutting corners to save half an hour or $20.

I'm going to be useing Rockford Fosgate Punch P2-10" dual 2ohm. They are perfect for this application and have a nice optional grill for an extra $10 that will protect them from the harsh reality of a functioning boot. All of this will be powered by two Response D-Class amplifiers. One 4x100W RMS @ 4ohm and one 1x600W RMS @ 2ohm. Yes you heard me correctly, that brand from Jaycar. Read the reveiws and save yourself a TON of money! They won best overall and best value for money in a TOP 10 amplifer shoot out in the US last year for D-Class. At their rated output they produce 0.008%T.H.D. @ 1kHz 0dB input. Not bad at all.

To help tighten the voltage I'm installing a 1 Farud Capacitor, and if need be I have located a bolt in replacement 160A alternator from the USA. But I'll cross that bridge when I come to it. Later on down the track will be a Rockford Fosgate 3Sixty.3 so I can tune the sucker properly, untill then it's a line converter (sigh) off the speaker out on the AVN H/U and the RCA sub out. This is what I have so far...

A lot of man-hours have gone into just doing this much but everything you see I have done myself. I will have to take the aluminum plates to a fabrication shop as I don't have folding or aluminium welding gear, but I will mark it up myself to ensure it fits right lol. I will post more as it all comes together.

Forgive my grammar and spelling, Skills like mine don't arrise out of an A+ in Year 12 English