Prelude

An oil cooler is certainly not something I would recommend for the majority of EZ30 owners- I’ll state that right at the start. They have the possibility of catastrophic engine damage if done incorrectly, not to mention the potential for annoying leaks and an increase in NVH. Before going all in on an oil cooler I would highly suggest determining if you actually need one; the factory oil system on these engines tends to be mostly adequate especially for street use.

I wouldn’t even consider doing this sort of modification if you don’t already have oil temperature and pressure sensors at a bare minimum. I logged mine over the course of 12 months, in hot and cold conditions, before deciding that this is something I should be implementing. Without this data this modification is likely to be a massive WOFTAM!

I never really had a problem with my oil temperature on the street, hitting a maximum of 125c through the hills on even the hottest days. This temperature is totally fine for a modern, high quality oil, and if you rarely saw it hotter than this I would suggest just running a good oil, like Motul Sport 5w40, which oil analysis on my car has shown practically no signs of breaking down after 5000km and two track days in the cooler months (where the oil would get to the low 130c’s). This would be a lot easier, safer and offer better piece of mind compared to fitting a dedicated cooler.

If you are routinely seeing oil temperatures hotter than 130c, however, such as on track or for boosted applications, an oil cooler might be a good idea. I would routinely see oil temperatures in the mid to high 140’s in 35c ambient temperatures at Winton, which is safe for a short period of time, but cooler than that would be better. Even at this temperature the high quality Motul would still see oil pressures comfortably above 18psi at idle, and above 75psi at 7000rpm, but oil analysis done after these hotter track days did show signs of faster oil degradation.

The added benefit of an oil cooler is removing some of the thermal load from the coolant system. If you are still daily driving the car I would highly recommend not removing the factory oil cooler/warmer, as on the freeway the car will struggle to get oil temperatures above 85c even with this fitted. With this part still fitted though there is significant energy transferred into the coolant; removing some of this heat load got me an additional ½ a hot lap before coolant temps got uncomfortably hot with the stock radiator.

EZ30 Oil and Coolant Cooling

9 posts

• Page 1 of 1

EZ30 Oil and Coolant Cooling

Last edited by JezzaH6 on Sat Aug 27, 2022 2:15 pm, edited 1 time in total.

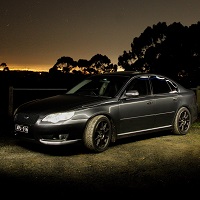

2007 Subaru Liberty 3.0r-b 6MT

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

Re: EZ30 Oil Cooling

So you've decided to run an oil cooler....

I didn’t want to fit an oil cooler behind the drivers side fog light- there is a lot of room here, but its position means it is more likely to be damaged in the event of an accident, plus I have Raptor’s CAI sitting at home waiting to go on and didn’t want to be heating up the air that the intake would be drawing from. I already see IAT’s 40+c above ambient on track!

I also wanted to keep the cooler out of the air stream for the radiator, which only left the minimal amount of space behind the passenger fog light, sitting in the space between the washer bottle and the bottom of the front bumper. Because of the limited space I was only able to fit a small cooler there, but with a surprising large amount of fresh air available to it and a good path for its exhaust it has proved to be quite efficient!

As space was limited I settled on a Fenix 10 row plate-and-fin style oil cooler, as these tend to be the most efficient and impose as little restriction to flow as possible. This cooler uses -AN10 style fittings for as little flow restriction as possible, and makes designing and constructing your own custom hoses very straightforward.

As the oil hoses will be running the full width of the car I chose to get double-braided lines to suit the -AN10 fittings. The downside of these is they aren’t particularly flexible, but with a Nylon inner braid and a woven stainless-steel outer braid it should help prevent any impacts cutting such an important hose.

I didn’t want to do any major modifications to the oiling system on the engine itself, which meant a sandwich plate with a built-in thermostat for the oil take-off was perfect. I used one made by Mishimoto, and I got the one that has dual 1/8” NPT ports so I didn’t have to use a ‘T’ for oil temperature and pressure sensors (part number MMOP-SPTR). The thermostat in this opens at 85c.

The layout of these is quite clever. The thermostat, when below its set temperature, holds open a bypass through the sandwich plate, but still allows a small amount of oil to flow through the oil cooler. Then ensures that when the bypass closes there isn’t a large amount of cold, thick oil that was already in the cooler getting dumped into a warm engine. When the oil is up to temperature this bypass is blocked off, forcing the full oil flow through the cooler.

I initially used Teflon tape to try and seal the adaptors that go from the M20x1.0 sandwich plate fittings to -AN10. However, these fittings seeped about 50-100ml of oil between services and made a bit of a mess. I have since redone these fittings with proper Dowty bonded seals, which are showing no signs of seepage after 20k kms. These seals are quite pricey but totally worth the money in situations like this.

I learnt the hard way that cheap -AN fittings are cheap for a reason. The ones that came with the hose both failed as I was tightening them, so I ended up going all in on some stunning Raceworks fittings! These worked great even with the double-braided hoses, and I have had zero issues with leaky fittings in the 18ish months I’ve been running the cooler.

These are very straightforward to assemble. I found an angle grinder to be the best tool for cutting the stainless braided hose, with minimal deburing required afterwards. The end of the hose can then be forced into the threaded end of the fitting, and then the whole assembly threads together. Tape around the hex sections helps prevent scratching the anodised aluminium, and a wrap of tape around the hose right after the fitting helps make sure it’s obvious if the hose is pushed out while the fitting is threaded together. A small drop of oil on the threaded sections of the fittings helps stop the relatively soft aluminium from galling as the assembly is tightened up.

A draw wire was used to drag small pieces of rag through the assembled lines to remove as much gunk as possible before filling the system with oil. I ended up also flushing the lines with some spare oil as well to ensure they were as clean as possible.

The hoses were run from the oil filter and behind the front aluminium smash bar to try and protect them as much as possible- the lines don’t extend out past any of the front crash protection at any point. I used -AN10 hose separators, modified so I could bolt them to the aluminium crash bar with riv-nuts. This is one thing that could be potentially improved upon- the hard mounting of the oil lines and cooler transfers a fair bit of vibration into the aluminium front bar, and causes quite a bit of noise. Some custom 3D printed flexible mounts are on the cards to see if this noise can be reduced- it sounds like a fairly loud hum that changes with changing engine RPM.

The cooler itself was mounted using a bracket made of aluminium, with the idea being to allow the cooler to be able to move fairly easily in the case of an accident and hopefully prevent it from rupturing. There is not much room in my chosen location; I had to change the angle of the windscreen washer pump, redo some of the pump and fog light wiring and change the routing of the washer hoses to get this to fit.

As the cooler was sitting well below where the factory under-tray extension of the wheel arch liners sits these plastic guards had to be cut off. As I did not want the cooler to be exposed to things possibly bouncing up and impacting it I made a guard out of 5mm thick 7075 aluminium, for its very high strength to weight properties. This guard bolts on to the wheel liner and the bumper, giving a smooth surface to protect the cooler from sticks and rocks, as well as smaller impacts, and funnels air through the cooler from the hollowed-out fog light surround.

The passenger fog light surround had its hexagons hollowed out to allow for easy airflow into the cooler area. As this left the surround looking quite empty, and had the possibility of letting sticks or rocks into the cooler area I also plastic-welded in some metal mesh to give the area another layer of protection. This has the additional benefit of making the hollowed-out section much harder to see! I now have two different guards; one hollowed out for track or hot summer days, and one closed off for cold weather freeway driving where I need every degree of oil temperature!

This guard has been tested late one night up in the Alpine National Park, where an unfortunate run-in with an approx 2kg rabbit at almost 100km/h right in the middle of the oil cooler’s location saw zero damage to the precious cooler! I have since also beefed up the front bumper in this location with some strips of aluminium bar and extra layers of fibreglass.

This small cooler has made a significant difference to the trackability of my car! With a small drop in ambient temperature (I have never had consistent track day temps….) the hottest I’ve seen my oil temperature is 126c. This is quite a significant drop for such a small cooler; I put this down to a relatively optimised placement and good air ducting; and I have never seen oil temperatures above 118c through the hills on even the hottest of days. Paired with a triple core 42mm thick alloy radiator this setup allows for consistent hot laps (until brake or tyre fade anyway) with zero cooling issues.

Another benefit of this is an increase in oil capacity- an oil change now takes the best part of 7 litres, and accompanied with the PBMS baffled sump plate the setup offers great piece of mind regarding oil starvation in higher g corners. The increase in oil capacity also helps dampen out sudden temperature fluctuations, where short sprints don’t get the oil as hot as it used to.

The downside to this is oil temperatures on the highway- these are only borderline warm enough and are another downside to a dedicated oil cooler. On these colder nights the car struggles to get the oil above 85c, and this is with the thermostatic sandwich plate and even going as far as blocking off the airflow through the cooler with tape. If the ambient temperature is above 20c the oil temps hover around 92-95c, which is much more comfortable.

I have also switched to a high-flow 84c coolant thermostat, with the intention of increasing coolant temps while on the highway, with subsequent increase in oil temperatures thanks to the factory oil warmer. This thermostat sees the coolant sit around 88-90c while cruising on the highway, but being high-flow allows the system to better utilise the larger volume of the upgraded radiator, and through the hills I have actually seen a reduction in coolant temperatures compared to the stock thermostat with the upgraded radiator.

I didn’t want to fit an oil cooler behind the drivers side fog light- there is a lot of room here, but its position means it is more likely to be damaged in the event of an accident, plus I have Raptor’s CAI sitting at home waiting to go on and didn’t want to be heating up the air that the intake would be drawing from. I already see IAT’s 40+c above ambient on track!

I also wanted to keep the cooler out of the air stream for the radiator, which only left the minimal amount of space behind the passenger fog light, sitting in the space between the washer bottle and the bottom of the front bumper. Because of the limited space I was only able to fit a small cooler there, but with a surprising large amount of fresh air available to it and a good path for its exhaust it has proved to be quite efficient!

As space was limited I settled on a Fenix 10 row plate-and-fin style oil cooler, as these tend to be the most efficient and impose as little restriction to flow as possible. This cooler uses -AN10 style fittings for as little flow restriction as possible, and makes designing and constructing your own custom hoses very straightforward.

As the oil hoses will be running the full width of the car I chose to get double-braided lines to suit the -AN10 fittings. The downside of these is they aren’t particularly flexible, but with a Nylon inner braid and a woven stainless-steel outer braid it should help prevent any impacts cutting such an important hose.

I didn’t want to do any major modifications to the oiling system on the engine itself, which meant a sandwich plate with a built-in thermostat for the oil take-off was perfect. I used one made by Mishimoto, and I got the one that has dual 1/8” NPT ports so I didn’t have to use a ‘T’ for oil temperature and pressure sensors (part number MMOP-SPTR). The thermostat in this opens at 85c.

The layout of these is quite clever. The thermostat, when below its set temperature, holds open a bypass through the sandwich plate, but still allows a small amount of oil to flow through the oil cooler. Then ensures that when the bypass closes there isn’t a large amount of cold, thick oil that was already in the cooler getting dumped into a warm engine. When the oil is up to temperature this bypass is blocked off, forcing the full oil flow through the cooler.

I initially used Teflon tape to try and seal the adaptors that go from the M20x1.0 sandwich plate fittings to -AN10. However, these fittings seeped about 50-100ml of oil between services and made a bit of a mess. I have since redone these fittings with proper Dowty bonded seals, which are showing no signs of seepage after 20k kms. These seals are quite pricey but totally worth the money in situations like this.

I learnt the hard way that cheap -AN fittings are cheap for a reason. The ones that came with the hose both failed as I was tightening them, so I ended up going all in on some stunning Raceworks fittings! These worked great even with the double-braided hoses, and I have had zero issues with leaky fittings in the 18ish months I’ve been running the cooler.

These are very straightforward to assemble. I found an angle grinder to be the best tool for cutting the stainless braided hose, with minimal deburing required afterwards. The end of the hose can then be forced into the threaded end of the fitting, and then the whole assembly threads together. Tape around the hex sections helps prevent scratching the anodised aluminium, and a wrap of tape around the hose right after the fitting helps make sure it’s obvious if the hose is pushed out while the fitting is threaded together. A small drop of oil on the threaded sections of the fittings helps stop the relatively soft aluminium from galling as the assembly is tightened up.

A draw wire was used to drag small pieces of rag through the assembled lines to remove as much gunk as possible before filling the system with oil. I ended up also flushing the lines with some spare oil as well to ensure they were as clean as possible.

The hoses were run from the oil filter and behind the front aluminium smash bar to try and protect them as much as possible- the lines don’t extend out past any of the front crash protection at any point. I used -AN10 hose separators, modified so I could bolt them to the aluminium crash bar with riv-nuts. This is one thing that could be potentially improved upon- the hard mounting of the oil lines and cooler transfers a fair bit of vibration into the aluminium front bar, and causes quite a bit of noise. Some custom 3D printed flexible mounts are on the cards to see if this noise can be reduced- it sounds like a fairly loud hum that changes with changing engine RPM.

The cooler itself was mounted using a bracket made of aluminium, with the idea being to allow the cooler to be able to move fairly easily in the case of an accident and hopefully prevent it from rupturing. There is not much room in my chosen location; I had to change the angle of the windscreen washer pump, redo some of the pump and fog light wiring and change the routing of the washer hoses to get this to fit.

As the cooler was sitting well below where the factory under-tray extension of the wheel arch liners sits these plastic guards had to be cut off. As I did not want the cooler to be exposed to things possibly bouncing up and impacting it I made a guard out of 5mm thick 7075 aluminium, for its very high strength to weight properties. This guard bolts on to the wheel liner and the bumper, giving a smooth surface to protect the cooler from sticks and rocks, as well as smaller impacts, and funnels air through the cooler from the hollowed-out fog light surround.

The passenger fog light surround had its hexagons hollowed out to allow for easy airflow into the cooler area. As this left the surround looking quite empty, and had the possibility of letting sticks or rocks into the cooler area I also plastic-welded in some metal mesh to give the area another layer of protection. This has the additional benefit of making the hollowed-out section much harder to see! I now have two different guards; one hollowed out for track or hot summer days, and one closed off for cold weather freeway driving where I need every degree of oil temperature!

This guard has been tested late one night up in the Alpine National Park, where an unfortunate run-in with an approx 2kg rabbit at almost 100km/h right in the middle of the oil cooler’s location saw zero damage to the precious cooler! I have since also beefed up the front bumper in this location with some strips of aluminium bar and extra layers of fibreglass.

This small cooler has made a significant difference to the trackability of my car! With a small drop in ambient temperature (I have never had consistent track day temps….) the hottest I’ve seen my oil temperature is 126c. This is quite a significant drop for such a small cooler; I put this down to a relatively optimised placement and good air ducting; and I have never seen oil temperatures above 118c through the hills on even the hottest of days. Paired with a triple core 42mm thick alloy radiator this setup allows for consistent hot laps (until brake or tyre fade anyway) with zero cooling issues.

Another benefit of this is an increase in oil capacity- an oil change now takes the best part of 7 litres, and accompanied with the PBMS baffled sump plate the setup offers great piece of mind regarding oil starvation in higher g corners. The increase in oil capacity also helps dampen out sudden temperature fluctuations, where short sprints don’t get the oil as hot as it used to.

The downside to this is oil temperatures on the highway- these are only borderline warm enough and are another downside to a dedicated oil cooler. On these colder nights the car struggles to get the oil above 85c, and this is with the thermostatic sandwich plate and even going as far as blocking off the airflow through the cooler with tape. If the ambient temperature is above 20c the oil temps hover around 92-95c, which is much more comfortable.

I have also switched to a high-flow 84c coolant thermostat, with the intention of increasing coolant temps while on the highway, with subsequent increase in oil temperatures thanks to the factory oil warmer. This thermostat sees the coolant sit around 88-90c while cruising on the highway, but being high-flow allows the system to better utilise the larger volume of the upgraded radiator, and through the hills I have actually seen a reduction in coolant temperatures compared to the stock thermostat with the upgraded radiator.

Last edited by JezzaH6 on Fri Aug 26, 2022 2:24 pm, edited 3 times in total.

2007 Subaru Liberty 3.0r-b 6MT

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

Re: EZ30 Oil Cooling

Excellent-write-up.

-

Yowie - Posts: 576

- Joined: Tue Jul 21, 2015 10:05 pm

- Location: Brisbane

- Car: SH Forester XT

Re: EZ30 Oil Cooling

JezzaH6 wrote:...

The added benefit of an oil cooler is removing some of the thermal load from the coolant system. If you are still daily driving the car I would highly recommend not removing the factory oil cooler/warmer, as on the freeway the car will struggle to get oil temperatures above 85c even with this fitted.

I suspect many H6 owners wouldn't even know the heater/cooler is there, if they hadn't had a detailed look under the engine.

I only discovered it when one of the rubber coolant hoses going to it failed, dumping most of my coolant on the freeway one evening. Enough dribbled on to my garage floor for me to realise the problem the next morning.

(Discovered it at 7am, down to my local Subaru at 8am, who said they'd have to get the part down from Sydney.

Went to Repco over the road and found a hose of similar diameter, and managed to install it and still get to work before 10am.)

-

Ric - Site Admin

- Posts: 6435

- Joined: Fri Oct 06, 2006 11:08 pm

- Location: Melbourne

- Car: OLD: MY06 3RB Wagon NEW: MY21 Outbck

- Real name: Ric

- Profile URL: viewtopic.php?f=7&t=12

Re: EZ30 Oil Cooling

Ric wrote:JezzaH6 wrote:...

The added benefit of an oil cooler is removing some of the thermal load from the coolant system. If you are still daily driving the car I would highly recommend not removing the factory oil cooler/warmer, as on the freeway the car will struggle to get oil temperatures above 85c even with this fitted.

I suspect many H6 owners wouldn't even know the heater/cooler is there, if they hadn't had a detailed look under the engine.

I only discovered it when one of the rubber coolant hoses going to it failed, dumping most of my coolant on the freeway one evening. Enough dribbled on to my garage floor for me to realise the problem the next morning.

(Discovered it at 7am, down to my local Subaru at 8am, who said they'd have to get the part down from Sydney.

Went to Repco over the road and found a hose of similar diameter, and managed to install it and still get to work before 10am.)

I wouldn't be at all surprised either- even with gauges it functions completely transparently. Definitely essential to keep this fitted on all but the most serious track cars to keep the temps in check while cruising long distances.

That really sucks. I've had a couple of hoses fail over the years and it is very much not fun. I noticed mine when the coolant temps started acting strangely on my digital gauge- the in-dash gauge never moved. Pretty lucky you were able to get it fixed that quickly and that it didn't cause any damage!

Last edited by JezzaH6 on Sat Aug 27, 2022 7:39 pm, edited 1 time in total.

2007 Subaru Liberty 3.0r-b 6MT

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

Re: EZ30 Oil Cooling

Since a boxer engine is, by nature, quite a wide engine, there is risk of oil moving out of the sump and into the outside cylinder head when the car is cornering with higher G forces. Unlike an EJ-series engine, however, the EZ only has a small steel lower oil pan; the majority of the oil volume is stored in the upper pan which is integrated into the block. This means there is only a small amount of space to fit a baffle, and there are no off-the-shelf extended capacity baffled sumps that I am aware of. It also means the area of the pan covered by the oil pickup is quite small, with oil starvation being a real possibility under higher G forces.

Possum Bourne Motorsport in New Zealand do make a baffle plate, however, which sits in between the steel lower pan and the aluminium upper pan. Since the EZ holds quite a lot of oil (even before adding the extra capacity in the oil cooler a full change takes over 6l), extra capacity is not strictly necessary, but the protection against oil starvation is definitely a bonus.

This is really easy to install. There is a bunch of bolts that hold the sump on; when these are removed a few knocks with a soft hammer will split the sealant. Resist the urge to poke anything sharp through the sealing surfaces as a scratch here will be almost impossible to seal! The plate can then have sealant spread over its top surface and installed, following the directions of the sealant. The lower pan can then be installed in the same way and the bolts torqued to spec.

I was glad to see minimal oil varnish and almost no metal on the sump magnet- a testament to regular oil changes!

I have never noticed any loss of oil pressure, even momentarily in the logs, and very minimal wear products are evident even after the 4 track days I did before fitting this baffle. However, the peace of mind this setup offers is worth its weight in gold, and although this is a fairly pricey piece of laser-cut stainless steel it is significantly cheaper than a full engine rebuild!

Possum Bourne Motorsport in New Zealand do make a baffle plate, however, which sits in between the steel lower pan and the aluminium upper pan. Since the EZ holds quite a lot of oil (even before adding the extra capacity in the oil cooler a full change takes over 6l), extra capacity is not strictly necessary, but the protection against oil starvation is definitely a bonus.

This is really easy to install. There is a bunch of bolts that hold the sump on; when these are removed a few knocks with a soft hammer will split the sealant. Resist the urge to poke anything sharp through the sealing surfaces as a scratch here will be almost impossible to seal! The plate can then have sealant spread over its top surface and installed, following the directions of the sealant. The lower pan can then be installed in the same way and the bolts torqued to spec.

I was glad to see minimal oil varnish and almost no metal on the sump magnet- a testament to regular oil changes!

I have never noticed any loss of oil pressure, even momentarily in the logs, and very minimal wear products are evident even after the 4 track days I did before fitting this baffle. However, the peace of mind this setup offers is worth its weight in gold, and although this is a fairly pricey piece of laser-cut stainless steel it is significantly cheaper than a full engine rebuild!

2007 Subaru Liberty 3.0r-b 6MT

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

Re: EZ30 Oil and Coolant Cooling

Good shit mate! I have one of those baffle plates to go into my new motor also

2007 3.0r Spec B Wagon "FWD911"

GT3582R turbo setup +/- 300awkw

PB: 12.04 @ 120.2mph (Sydney dragway 3/2/21)

https://www.youtube.com/watch?v=YV3e7YHqIYU

https://www.youtube.com/watch?v=9VbfFJJpcz0

(Built engine in the works)

@taj.fwd911 on instagram for more!

GT3582R turbo setup +/- 300awkw

PB: 12.04 @ 120.2mph (Sydney dragway 3/2/21)

https://www.youtube.com/watch?v=YV3e7YHqIYU

https://www.youtube.com/watch?v=9VbfFJJpcz0

(Built engine in the works)

@taj.fwd911 on instagram for more!

-

Taj - Posts: 29

- Joined: Tue May 10, 2016 6:47 pm

- Location: Sydney

- Car: MY07 3.0R spec B Wagon

Re: EZ30 Oil and Coolant Cooling

Taj wrote:Good shit mate! I have one of those baffle plates to go into my new motor also

Cheers! It's a very nice piece- great for piece of mind and makes a lot of sense on a turbo build

2007 Subaru Liberty 3.0r-b 6MT

-

JezzaH6 - Posts: 104

- Joined: Thu Jun 11, 2020 6:57 pm

- Location: Melbourne

- Car: 2007 3.0r-b 6MT

- Real name: Jeremy

- Profile URL: viewtopic.php?f=10&t=36687&p=450058#p450058

9 posts

• Page 1 of 1

Return to 3.0R & 3.6R engine specific

Who is online

Users browsing this forum: No registered users and 4 guests